Register with Plumtri!

Register on plumtri as an Individual or as an Organisation to gain access to all of its useful features and remain updated on the latest R&I news, events and funding opportunities.

-

Welcome to plumtriA platform for Research & Innovation

Welcome to plumtriA platform for Research & Innovation -

Looking for Funding?Check out the current open calls

Looking for Funding?Check out the current open calls -

Register today to start receiving our monthly newsletter

Register today to start receiving our monthly newsletter -

Looking to partner up?Search our list of registered profiles

Looking to partner up?Search our list of registered profiles -

You have questions on a particular funding programme?

You have questions on a particular funding programme?

Project: ACTIVE

Surface disinfectants have become the unsung heroes of our modern world, especially in the wake of recent global health crises. With the onset of the COVID-19 pandemic, their significance skyrocketed as they emerged as the frontline defence against infectious diseases. However, behind their widespread use lies a complex supply chain from production to distribution. Enter Project ACTIVE: a groundbreaking initiative poised to revolutionise how we access surface disinfectants.

Unravelling Supply-Chain Struggles in the Disinfectant World

Traditionally, surface disinfectants are manufactured in centralised facilities and distributed across various sectors including healthcare, hospitality, and consumer markets. However, the fragility of this system became painfully apparent during the COVID-19 pandemic.

As demand for disinfectants surged to unprecedented levels, supply chain disruptions ensued, leaving hospitals, businesses, and individuals scrambling for access. From shortages of key ingredients like ethanol and hydrogen peroxide to logistical bottlenecks in transportation and distribution, every link in the chain felt the strain. As hospitals struggled to procure enough disinfectants to keep patients safe, the inherent vulnerabilities of centralised production and distribution models became clear.

Project ACTIVE: A New Hope for Disinfectant Supply

Amidst the chaos, Project ACTIVE emerged with a novel solution to the supply chain woes plaguing the disinfectant industry. At its core, Project ACTIVE seeks to decentralise disinfectant production by introducing on-site manufacturing devices capable of producing certified disinfectants without reliance on traditional supply chains.

Unlike conventional models that depend on a complex network of suppliers and distributors, Project ACTIVE empowers end-users to produce their own disinfectants on site, thereby eliminating the vulnerabilities associated with centralised production and distribution. This paradigm shift enhances supply chain resilience and ensures the continuity of disinfectant supply, even in the face of unprecedented challenges.

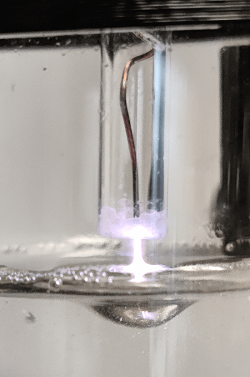

Central to Project ACTIVE’s success is its innovative approach to disinfectant production, which leverages cutting-edge non-thermal plasma technology. By harnessing the power of non-thermal plasma to generate disinfectant solutions from basic ingredients like water, Project ACTIVE offers a sustainable and scalable alternative to traditional manufacturing methods.

How Project ACTIVE Could Shake Up the Disinfectant Industry

By decentralising production and empowering end-users to take control of their disinfection needs, Project ACTIVE has the potential to reshape the disinfectant industry fundamentally. Rather than relying on large inventories of pre-manufactured disinfectants, Project ACTIVE enables organisations to stockpile production devices instead, thereby reducing reliance on centralised supply chains and ensuring greater flexibility in responding to fluctuations in demand.

Moreover, Project ACTIVE introduces the concept of a parallel supply chain, wherein end-users can supplement traditional supply channels with on-site production capabilities. This mitigates the risk of supply chain disruptions and fosters greater resilience and self-sufficiency within communities.

Real-life examples of Project ACTIVE in action further underscore its disruptive potential. For example, having the capability to create disinfectants on site equips remote and resource-poor hospitals with the ability to ensure adequate disinfection. Thus, from healthcare facilities ensuring uninterrupted access to disinfectants during periods of high demand to businesses bolstering their resilience against supply chain disruptions, such as those that occurred during the COVID-19 pandemic, the benefits of Project ACTIVE are tangible and far reaching.

Non-thermal plasma discharges over liquids. These discharges activate the liquid through chemical reactions initiated by reactive oxygen species that cause the formation of antimicrobial compounds such as hydrogen peroxide.

Teamwork Makes the Dream Work: The People Behind Project ACTIVE

While the technology behind Project ACTIVE is impressive, it’s the dedicated team of scientists and experts driving the project forward that truly sets it apart. Comprising physicists, biologists, chemists, and other specialists, this multidisciplinary team brings together a diverse range of expertise to tackle the complex challenges associated with disinfectant production.

At the heart of the project is a collaborative spirit that transcends traditional disciplinary boundaries. Each member of the team plays a crucial role, from developing plasma technology to refining the chemical composition of the disinfectant. By harnessing its members’ collective knowledge and expertise, Project ACTIVE embodies the power of teamwork in driving scientific innovation.

Despite the inherent challenges of working across disciplines, the Project ACTIVE team remains united by a shared vision of revolutionising the disinfectant industry. Through collaboration, communication, and shared commitment to excellence, they continue to push the boundaries of what is possible, paving the way for a brighter, safer future.

Project ACTIVE (R&I-2022-015L) financed by the Malta Council for Science & Technology, for and on behalf of the Foundation for Science and Technology, through the FUSION: R&I Technology Development Programme LITE.